Additive Manufacturing with Metal Powders Market Volume Worth 36,872.60 Tons by 2035

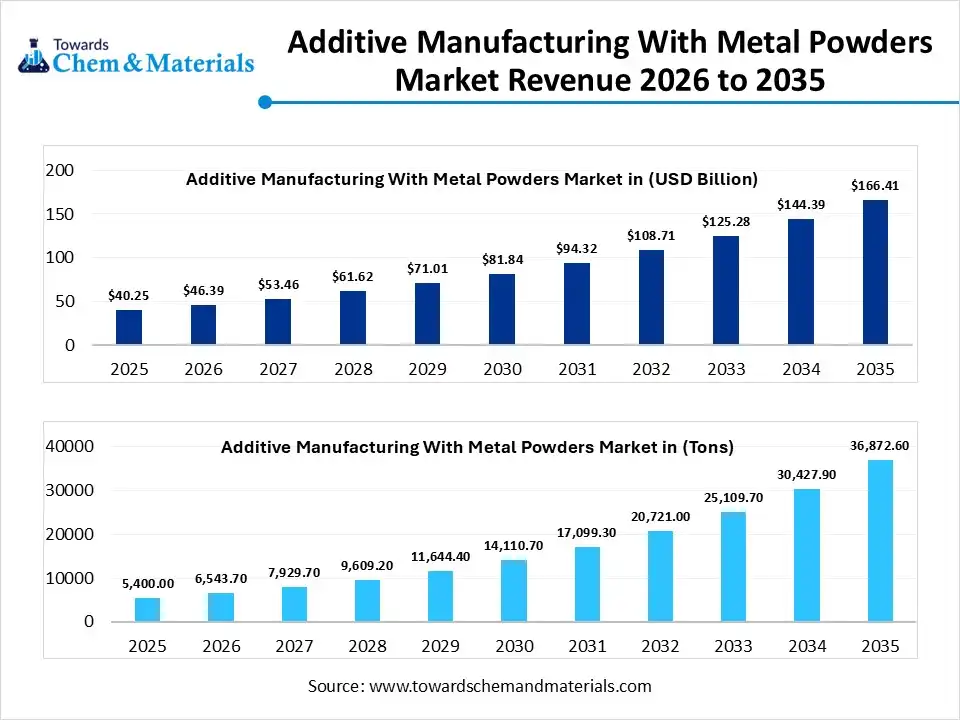

According to Towards Chemical and Materials, the global additive manufacturing with metal powders market volume was valued at 5,400.00 tons in 2025 and is expected to be worth around 36,872.60 tons by 2035, exhibiting at a compound annual growth rate (CAGR) of 21.18% over the forecast period from 2026 to 2035.

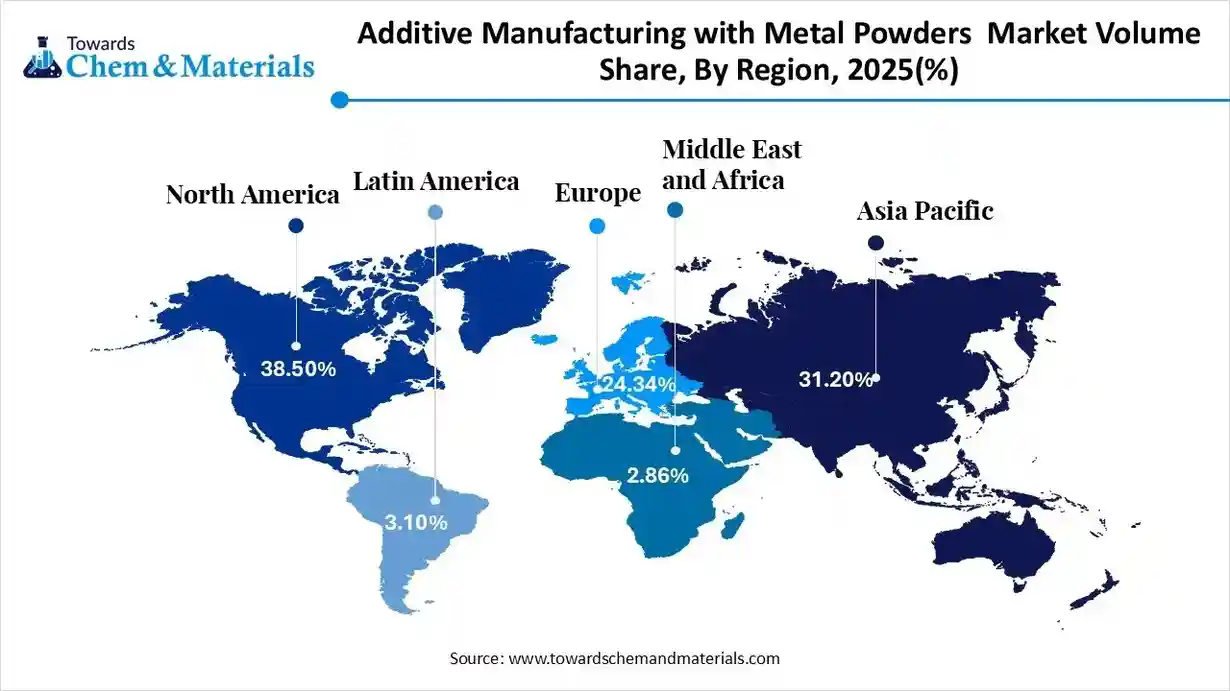

Ottawa, Jan. 28, 2026 (GLOBE NEWSWIRE) -- The global additive manufacturing with metal powders market size was estimated at USD 40.25 billion in 2025 and is expected to increase from USD 46.39 billion in 2026 to USD 166.41 billion by 2035, growing at a CAGR of 15.25% from 2026 to 2035. In terms of volume, the market is projected to grow from 5,400.00 tons in 2025 to 36,872.60 tons by 2035. growing at a CAGR of 21.18% from 2026 to 2035. North America dominated the additive manufacturing with metal powders market with the largest volume share of 38.5% in 2025. The market is driven by the circular economy, rising demand for specialty alloys, and industrial expansion. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/download-sample/6139

What are the Additive Manufacturing with Metal Powders?

The additive manufacturing with metal powders reduced material wastage and improved material efficiency. The demand for high-performance components and their diversified applications in aerospace, automotive, defense, and healthcare enable their expansion by integrating with hybrid manufacturing.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.com

Additive Manufacturing with Metal Powders Market Report Highlights

- North America dominated the additive manufacturing with metal powders market with the largest volume share of 38.50% in 2025.

- The additive manufacturing with metal powders market in Asia Pacific is expected to grow at a substantial CAGR of 24.62% from 2026 to 2035.

- The Europe additive manufacturing with metal powders market segment accounted for the major volume share of 24.34% in 2025.

- By material type, the stainless-steel segment dominated the market and accounted for the largest volume share of 38.4% in 2025.

- By material type, the titanium alloys segment is expected to grow at the fastest CAGR of 24.70% from 2026 to 2035 in terms of volume.

- By technology (process), the powder bed fusion (PBF) segment led the market with the largest revenue volume share of 76.20% in 2025.

- By powder production method, the gas atomization segment dominated the market and accounted for the largest volume share of 68.40% in 2025.

- By application area, the functional part production segment led the market with the largest revenue volume share of 52% in 2025.

- By end-use sector, the aerospace & defense segment dominated the market and accounted for the largest volume share of 39.80% in 2025.

Additive Manufacturing with Metal Powders Market Report Scope

| Report Attribute | Details |

| Market Size and Volume in 2026 | USD 46.39 Billion / 6543.70 Tons |

| Revenue Forecast in 2035 | USD 166.41 Billion / 36872.60 Tons |

| Growth Rate | CAGR 15.25% |

| Forecast Period | 2026 - 2035 |

| Base Year | 2025 |

| Units Considered | Value (Billion / Million), Volume (Tons) |

| Dominant Region | North America |

| Segment Covered | By Material Type (Feedstock), By Technology (Process), By Powder Production Method, Application, By End-Use Sector, By Region |

| Key companies profiled | Hoganas AB, Sandvik AB (Osprey®), Carpenter Technology (Carpente Additive), GKN Powder Metallurgy, AP&C (A GE Additive Company), Oerlikon AM, ATI (Allegheny Technologies), Rio Tinto Metal Powders, Kymera International, H.C. Starck, LPW Technology, Erasteel |

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6139

Private Industry Investments for Additive Manufacturing with Metal Powders:

- AML3D secured A$30 million in late 2024 to expand its global presence, particularly in the United States, for its wire arc additive manufacturing technology used for large-format metal parts.

- Desktop Metal received a major investment led by KDT in a Series E round to drive the adoption of its metal 3D printers for both mass production and office-friendly systems.

- Elementum 3D secured funding to develop a range of proprietary, high-performance aluminum, nickel, and titanium metal powders that can be successfully used in standard 3D printing processes.

- EOS GmbH is investing $3 million to expand its US metal additive manufacturing capacity, underscoring the demand for industrial metal printing solutions and services.

-

MX3D raised €7 million in a Series A round in May 2025 to accelerate the global deployment of its robotic Wire Arc Additive Manufacturing (WAAM) systems and expand its print-on-demand services.

What Are the Major Trends in the Additive Manufacturing with Metal Powders Market?

- Circular Economy & Powder Recycling: The growing focus on sustainability and closed-loop recycling technologies supports manufacturers in meeting stringent carbon neutrality targets without degrading chemical purity and lowering material cost.

- Shift Towards High-Volume Serial Production: The industry is increasingly moving from rapid prototyping to large-scale manufacturing in aerospace, automotive and medical sectors, utilizing 3D printing in the production of flight-certified and clinical-grade end-use parts.

-

Supply Chain Localization and Reshoring: Government incentives for domestic manufacturing of crucial alloys and metal powder to reduce reliance on international shipping and material suppliers.

Immediate Delivery Available | Buy This Premium Research Report@

https://www.towardschemandmaterials.com/checkout/6139

Additive Manufacturing with Metal Powders Market Dynamics

Driver

Demand for Specialty Alloys

The rising demand for hypersonic flight and clean energy sectors is driving the expansion of refractory metals like tungsten and molybdenum, and high-entropy alloys, which are fostering innovation in material science, useful in applications in nuclear energy and provide heat and corrosion resistance.

Restraints

High Material Costs and Strict Regulations

The market is restrained by the high material and operational costs for metal powder, and the stringent environmental regulations with complex certifications and regulatory requirements for new materials and processes limit the market adoption.

Opportunity

The Expansion in Aerospace & Automotive

The rising demand in the aerospace and automotive industries is driving the opportunity for high-performance component manufacturing and spare parts production that offer lightweight and high-strength. By using additive manufacturing, manufacturers achieve improved fuel efficiency and reduce lead times.

Technological Advancement and AI Additive Manufacturing with Metal Powders Industry

Technological innovation led to the adoption of automated and closed-loop powder handling by maintaining chemical purity and particle size distribution by integration of Direct Energy Deposition (DED) with CNC machining, which allows precision finishing. Additionally, the implementation of digital warehousing and distributed manufacturing significantly reduces logistics costs and carbon footprint.

Additive Manufacturing with Metal Powders Market Segmentation Insights

Material Type Insights

How Did the Stainless-Steel Segment Dominate the Additive Manufacturing with Metal Powders Market?

Stainless steel remains dominant in the market due to its versatility, affordability, and extensive use in automotive and heavy industrial sectors for fixtures, tooling, and functional prototypes. Its corrosion resistance and mechanical strength, supported by mature supply chains ensuring quality, drive its mainstream industrial production.

The titanium alloys segment is anticipated to grow fastest, driven by demand for lightweight, high-strength parts in aerospace and medical industries. Their biocompatibility and temperature resistance make them ideal for orthopedic implants and next generation jet engines. Advances in powder atomization and recycled titanium supply chains are reducing costs, positioning titanium as a key driver of innovation in mission-critical manufacturing due to its superior performance.

Technology (Process) Insights

Which Technology Segment Dominates the Additive Manufacturing with Metal Powders Market?

The powder bed fusion (PBF) segment maintains its market dominance due to its ability to produce high-density, complex shape parts. Its adoption in aerospace and healthcare for turbine blades and implants by achieving superior accuracy and mechanical properties. The technological development with improvements in alloy compatibility and advancement in multi-laser systems significantly increases build speeds and large-scale production.

The binder jetting segment offers significant growth during the projected period, mainly due to its capacity for large-scale, high-speed industrial production. Its exceptional property of operating at room temperature, it reduces waste and post-processing time, making it cost-effective for automotive and aerospace applications. Advancements in automated sintering and binder chemistry will enhance its sustainability and energy efficiency

Powder Production Method Insights

Why did the Gas Atomization Segment hold the biggest share in the Additive Manufacturing with Metal Powders Market?

Gas atomization secures its leading role by producing ultra-spherical, high-purity metal powders vital for high-performance 3D printing. It scales the production of specialty alloys like nickel-based superalloys and aerospace-grade titanium, ensuring flowability and packing density for industrial parts. This process drives global supply chains, enabling mass manufacturing of critical aerospace and medical components, with ongoing improvements in inert gas efficiency. It bridges metallurgical precision and high-volume demand, remaining crucial for advanced additive manufacturing.

The plasma atomization segment is experiencing the fastest growth in the market during the projected period by producing high-purity, spherical, low-oxygen powders with excellent flowability, which is essential for aerospace and medical sectors, where the key requirement is defect reduction and structural integrity. Its superior quality and lower oxygen give plasma atomization an edge over traditional methods as the industry adopts more specialized alloys and stricter regulatory standards.

Application Area Insights

How did the Functional Part Production Segment Dominate the Additive Manufacturing with Metal Powders Market?

Functional part production leads due to the development of metal 3D printing from prototype to high-volume manufacturing, especially in aerospace, defence, and healthcare. These sectors rely on additive manufacturing for mission-critical parts with superior strength-to-weight ratios and complex designs, achieving certifications and standards for industrial use. This provides 3D printed part consolidation and performance, supported by industrial alloys and automated quality control, making it the key growth driver and standard for advanced precision production.

The repair & maintenance segment is set to experience the fastest growth during the forecast period, driven by its cost-effectiveness and industries preferred restoring high-value parts over replacing them. The techniques, like Directed Energy Deposition extending component lifespan and reduce downtime. This trend toward sustainable refurbishment and industry adoption, like in heavy machinery and large-scale metal parts, accelerates market expansion.

End-Use Sector Insights

How did the Aerospace & Defense Segment hold the Largest Share of the Additive Manufacturing with Metal Powders Market?

The aerospace & defense segment dominated the market, driven by industrial need for lightweighting and part consolidation, where advanced titanium and nickel superalloys are used to manufacture flight-certified turbine blades, fuel nozzles, and structural components, catalyzing high-performance metal powder innovation. They optimize fuel efficiency by acting as key engines for growth and technological advancement.

The medical & dental are an emerging segment projected to grow at a CAGR between the projected period, due to its clinical superiority, increasing oral health awareness and aging population. The technological innovation is improving service delivery, policy and insurance support. Additionally, healthcare provider increasingly adopting digital workflows, which leads the market and continuous innovation for high-performance biocompatible powders.

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

Regional Insights

How did North America Dominate the Additive Manufacturing with Metal Powders Market?

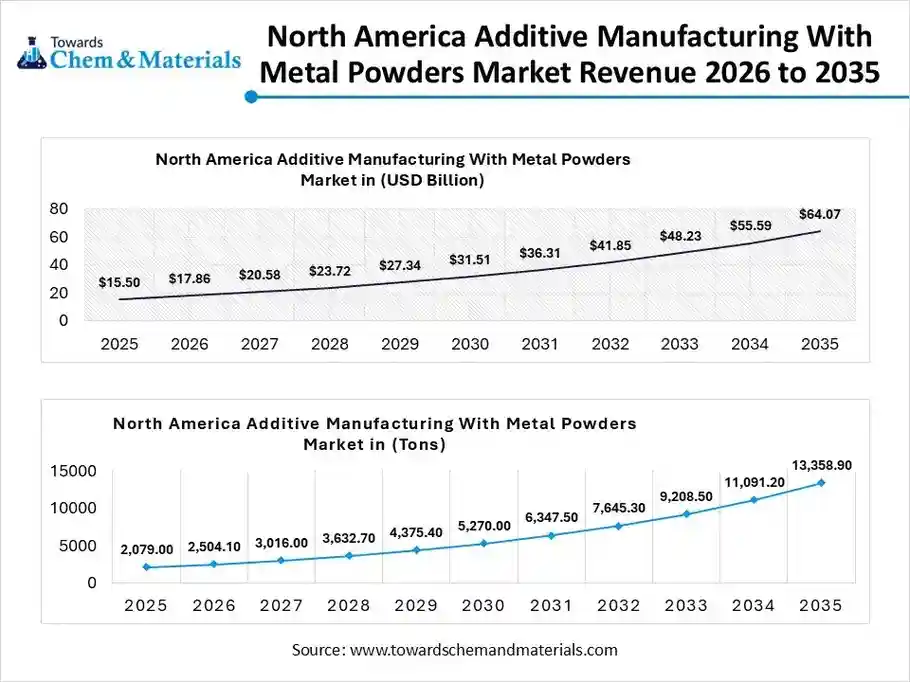

The North America additive manufacturing with metal powders market size was valued at USD 15.50 billion in 2025 and is expected to be worth around USD 64.07 billion by 2035, exhibiting at a compound annual growth rate (CAGR) of 15.27% over the forecast period from 2026 to 2035.

The North America additive manufacturing with metal powders market volume was estimated at 2,079.0 tons in 2025 and is projected to reach 13,358.9 tons by 2035, growing at a CAGR of 22.96% from 2026 to 2035.

North America leads in the global metal powders market, driven by well-established industrial systems and early advantages of its major economies. The integration of metal 3D printing in aerospace, defence, and healthcare sectors, using advanced titanium, nickel superalloys, and biocompatible powders for orthopedic and dental implants.

Federal initiatives such as AM forward and NSF programs promote supply chain and workforce development, with growing emphasis on sustainable manufacturing involving recycled powders and carbon tracking, strengthening North America’s leadership in industrial and environmental performance.

U.S. Additive Manufacturing with Metal Powders Market Trends

The U.S. market is growing as the aerospace, defense, automotive, and healthcare industries increase 3D printing adoption. Demand is rising for high-performance powders such as titanium, nickel, and stainless steel. Investments in domestic production and R&D are strengthening supply chains and manufacturing capabilities.

Why is Asia Pacific the Fastest-Growing Region in the Additive Manufacturing with Metal Powders Industry?

The Asia Pacific region is rapidly becoming the top growth area for metal powder additive manufacturing, fueled by rapid industrialization, electric vehicles, and electronics expansion. Government initiatives focus on manufacturing self-sufficiency and localized production of sophisticated hardware. By integrating metal 3D printing into large-scale manufacturing and leveraging rising middle-class demand for advancement, the region is transforming into material innovation and cost-effective precision engineering.

China Additive Manufacturing with Metal Powders Market Trends

China's market using metal powders is expanding rapidly as demand grows across the aerospace, automotive, and healthcare sectors, with metal powders being the largest and fastest-growing segment in the broader 3D printing powder market. The country's market shows strong projected growth, driven by industrial adoption, government support, and increasing local production capacity that reduces reliance on imports.

More Insights in Towards Chemical and Materials:

Asia Pacific Plastic Additives Market Size to Reach USD 40.29 Billion by 2034

Plastic Additives Market Size to Hit USD 89.83 Billion by 2034

Performance Additives Market Size to Reach USD 270.58 billion by 2034.

Specialty Fuel Additives Market Size to Hit USD 22.4 Billion by 2034

Lubricant Additives Market Size to Reach USD 28.19 Bn by 2034

Antimicrobial Additives Market Size to Reach USD 8.39 Bn By 2034

Antimicrobial Textile Market Size to Hit USD 25.55 Billion by 2035

Structural Adhesives Market Size to Surpass USD 25.31 Billion by 2035

Surface Treatment Chemical Market Size to Hit USD 14.51 Billion by 2035

Antimicrobial Plastic Market Size to Hit USD 109.50 Billion by 2035

Global Silicone Elastomer Market Size to Hit USD 19.00 Billion by 2035

Rubber Process Oil Market Size to Hit USD 3.49 Billion by 2035

Fire Fighting Chemicals Market Size to Hit USD 4.88 Billion by 2035

Polypropylene Random Copolymer Market Size to Hit USD 26.33 Billion by 2035

Road Marking Paint Market Size to Surpass USD 4.94 Billion by 2035

Industrial Cleaning Chemicals Market Size to Surpass USD 81.97 Billion by 2035

Cathodic Protection Market Size to Hit USD 11.85 Billion by 2035

Graphite Electrode Market Size to Hit USD 32.18 Bn by 2035

Membrane Filtration Market Size to Hit USD 54.40 Bn by 2035

Water Treatment Membrane Market Size to Reach USD 23.64 Bn by 2035

What is Going on Around the Global Additive Manufacturing with Metal Powders Industry:

-

In October 2025, Continuum Powders and HP Additive Manufacturing Solutions announced a collaboration to advance binder jet material innovation using HP’s Metal Jet S100 Printing Solution. This partnership focuses on high-performance parts and reducing supply chain risk.

Top Market Players in Additive Manufacturing with Metal Powders Market & Their Offerings:

Tier 1:

- Höganäs AB: Provides a vast range of forAM® iron, nickel, and titanium powders optimized for various 3D printing technologies.

- Sandvik AB (Osprey®): Delivers high-quality gas-atomized Osprey® powders including specialty alloys and customized material chemistries.

- Carpenter Technology (Carpenter Additive): Offers premium specialty alloy powders combined with complete material lifecycle and powder management services.

- GKN Powder Metallurgy: Supplies atomized metal powders while providing full-scale industrial 3D printing production for automotive and industrial sectors.

- AP & C (A GE Additive Company): Specializes in high-purity, spherical titanium and reactive metal powders produced via plasma atomization.

- ATI (Allegheny Technologies): Produces advanced titanium and nickel-based superalloy powders designed for high-performance aerospace and defense applications.

-

Oerlikon AM: Combines specialized MetcoAdd™ metal powders with comprehensive design, manufacturing, and post-processing services.

Tier 2:

- Rio Tinto Metal Powders

- Kymera International

- H.C. Starck

- LPW Technology

- Erasteel

Additive Manufacturing with Metal Powders Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2035. For this study, Towards Chemical and Materials has segmented the global Additive Manufacturing with Metal Powders Market

By Material Type (Feedstock)

- Stainless Steel

- Titanium Alloys

- Nickel-Based Superalloys

- Aluminum Alloys

- Cobalt-Chrome Alloys

- Precious Metals

By Technology (Process)

- Powder Bed Fusion (PBF)

- Selective Laser Melting (SLM) / Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

- Directed Energy Deposition (DED)

- Laser Engineering Net Shaping (LENS)

- Electron Beam Additive Manufacturing (EBAM)

- Binder Jetting

- Metal Extrusion (Bound Powder Extrusion)

By Powder Production Method

- Gas Atomization

- Plasma Atomization

- Water Atomization

- Mechanical Milling

By Application Area

- Prototyping

- Functional Part Production

- Tooling & Molds

- Repair & Maintenance

By End-Use Sector

- Aerospace & Defense

- Medical & Dental

- Automotive

- Energy & Power

- Consumer Goods

By Region

North America:

- U.S.

- Canada

- Mexico

- Rest of North America

South America:

- Brazil

- Argentina

- Rest of South America

Europe:

- Western Europe

- Germany

- Italy

- France

- Netherlands

- Spain

- Portugal

- Belgium

- Ireland

- UK

- Iceland

- Switzerland

- Poland

- Rest of Western Europe

Eastern Europe:

- Austria

- Russia & Belarus

- Türkiye

- Albania

- Rest of Eastern Europe

Asia Pacific:

- China

- Taiwan

- India

- Japan

- Australia and New Zealand,

- ASEAN Countries (Singapore, Malaysia)

- South Korea

- Rest of APAC

MEA:

- GCC Countries

- Saudi Arabia

- United Arab Emirates (UAE)

- Qatar

- Kuwait

- Oman

- Bahrain

- South Africa

- Egypt

- Rest of MEA

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6139

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics | TCM Blog

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.